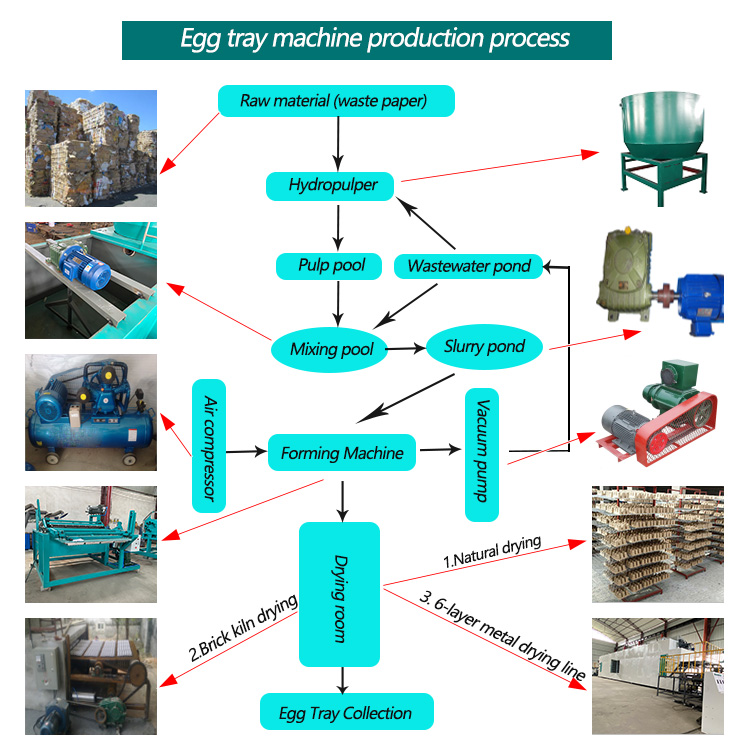

Mutsetse wekugadzira tireyi yezai yeYoung Bamboo pulp otomatiki unonyanya kushandisa mapepa emarara sezvinhu zvakabikwa, ane manyuko akapfuma uye mitengo yakaderera, uye ibudiriro yakazara uye kushandiswa kwemarara. Mvura inoshandiswa mukugadzirwa kwayo inovharwa uye inodzokororwa, hapana mvura yakasviba kana gasi rinobuda. Mushure mekunge zvigadzirwa zve pulp molding zvashandiswa, marara anogona kudzokororwa sepepa rakajairika. Kunyangwe akasiyiwa munzvimbo yechisikigo, zviri nyore kuora nekuora kuita bepa rakajairika. Zvinhu zve organic zvigadzirwa zvine hushamwari kune nharaunda. Pepa remarara rinowedzerwa ku pulper uye mvura inotumirwa kutangi rekuchengetera. Pulp iri mutangi rekuchengetera inotamiswa zvakaenzana kutangi rekugovera nemuchina wekusanganisa. Pulp iri mutangi rekugovera inokurunga kusvika pakuwanda kwakati uye inotumirwa kumuchina wekuumba. Muchina wekuumba unogadzira tireyi yezai kubhandi reConveyor. Bhandi rekutakura rinopfuura nemumutsetse wekuomesa kuti tireyi yezai iome, uye pakupedzisira rinounganidzwa uye rinopakwa. Pamusoro pezvo, pombi ye vacuum inogona kupomba mvura isina kushandiswa mumuchina wekuumba kuenda kutangi rekumvura yekumashure. Tangi rekumashure rinogona kutakura mvura kuenda ku pulper netangi rekuchengetera pulp, uye mvura inogona kudzokororwa.

Zvinhu zvakagadzirwa zvinobva pamabhodhi akasiyana-siyana e pulp akadai se reed pulp, straw pulp, slurry, bamboo pulp ne wood pulp, uye marara paperboard, marara paper box paper, marara white paper, marara tail pulp waste, nezvimwewo. Marara paper, anowanikwa munzvimbo dzakawanda uye ari nyore kuunganidza. Munhu anodiwa ivanhu vashanu/kirasi: munhu mumwe chete munzvimbo ye pulping, munhu mumwe chete munzvimbo ye molding, vanhu vaviri mungoro, uye munhu mumwe chete mupakeji.

| Muenzaniso weMuchina | 1*3 | 1*4 | 3*4 | 4*4 | 4*8 | 5*8 | 5*12 | 6*8 |

| Goho (p/h) | 1000 | 1500 | 2500 | 3000 | 4000-4500 | 5000-6000 | 6000-6500 | 7000 |

| Pepa Remarara (kg/h) | 80 | 120 | 160 | 240 | 320 | 400 | 480 | 560 |

| Mvura (kg/h) | 160 | 240 | 320 | 480 | 600 | 750 | 900 | 1050 |

| Magetsi (kw/h) | 36 | 37 | 58 | 78 | 80 | 85 | 90 | 100 |

| Nzvimbo Yemusangano | 45 | 80 | 80 | 100 | 100 | 140 | 180 | 250 |

| Nzvimbo Yokuomesa | Hapana chikonzero | 216 | 216 | 216 | 216 | 238 | 260 | 300 |

2.Simba rinoreva zvikamu zvikuru, kwete mutsetse wekuomesa

3. Chiyero chose chekushandiswa kwemafuta chinoverengerwa ne60%

4.Kureba kwemutsetse wekuomesa we single 42-45 metres, double layer 22-25 metres, multi layer inogona kuchengetedza nzvimbo yeworkshop

-

YB-1*3 muchina wekugadzira tireyi yezai 1000pcs/awa ye bu...

-

Otomatiki bepa pulp zai tireyi kugadzirwa mutsetse / ...

-

Young Bamboo bepa zai tireyi kugadzira muchina auto ...

-

Otomatiki marara bepa pulp zai tireyi kugadzira mach ...

-

1*4 marara epepa Pulp Moulding yekuomesa tireyi yezai Ma...

-

Muchina wekugadzira mapurasitiki ekuzadza matinji emuchina wekugadzira matinji madiki ...