1. Mutsetse wekugadzira Pulp Moulding unozivikanwa semutsetse wetireyi yezai wekushandisa zvakanyanya mukugadzira tireyi yezai.

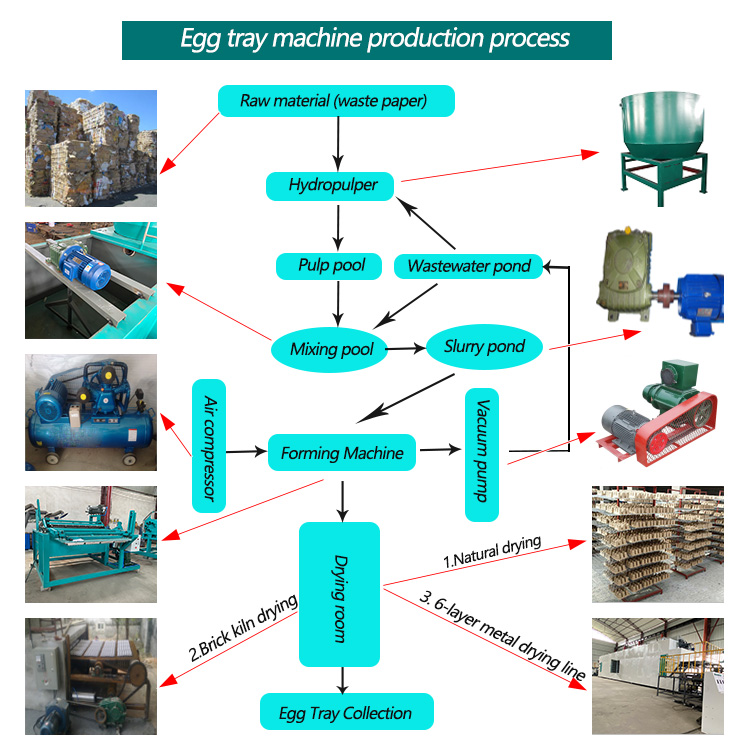

2. Mutsetse wekugadzira Pulp Moulding, unoshandisa mapepa akaraswa, kadhibhodhi, zvinhu zvasara zvemuchina wepepa, uchishandisa hydraulic pulper, musanganiswa unogadzira pulp yakakora, uye pulp inotorwa ne vacuum yesimbi yakakosha kuti ive zvigadzirwa zvakanyorova, kuburikidza nekuomesa, uye kuumba kuti ive zvigadzirwa zvakapedzwa.

3. Kugadzira Pulp Moulding Line kunoshandisa mvura yakadzokororwa uye hakukonzere kusvibiswa kwemvura kana mhepo. Zvigadzirwa zvepurasitiki zvinopedzwa zvinogona kudzokororwa mushure mekushandiswa mukuchengetedza, kutakurwa, uye kutengesa. Mushure mekupwanya, zviri nyore kuora sepepa, kunyangwe zvikaraswa munzvimbo yechisikigo.

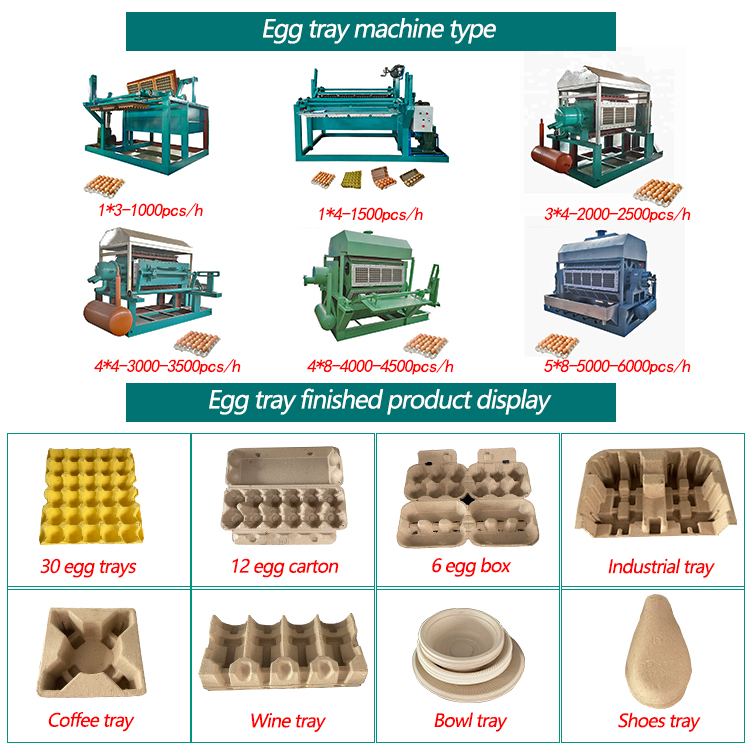

4. Mitsetse yekugadzira otomatiki ye pulp molding inogona kugadzirwa nemidziyo yakasiyana-siyana yechikafu, tireyi yezai, mabhokisi emasikati nezvimwewo.

| Muenzaniso weMuchina | 1*3/1*4 | 3*4/4*4 | 4*8/5*8 | 5*12/6*8 |

| Goho (p/h) | 1000-1500 | 2500-3000 | 4000-6000 | 6000-7000 |

| Pepa Remarara (kg/h) | 80-120 | 160-240 | 320-400 | 480-560 |

| Mvura (kg/h) | 160-240 | 320-480 | 600-750 | 900-1050 |

| Magetsi (kw/h) | 36-37 | 58-78 | 80-85 | 90-100 |

| Nzvimbo Yemusangano | 45-80 | 80-100 | 100-140 | 180-250 |

| Nzvimbo Yokuomesa | Hapana chikonzero | 216 | 216-238 | 260-300 |

Kutyaira mota yeservo kwakanyatsogadzirwa, kushanda zvakanaka uye tambo yekuomesa inochengetedza simba.

1, Shandisa injini yeservo inogadzirisa zvinhu nenzira chaiyo kuti ive nechokwadi chekuti inoshanda nekukurumidza.

2, Shandisa absolute encoder kuti uwane kugadzirisa kwakarurama.

3, Kushandiswa kwesimbi yebronze casting static uye dynamic ring structure kwakakodzera zvakanyanya pakubviswa kwemvura muchigadzirwa.

4, Kushandiswa kwechimiro chemuchina kuona kuti mold yakavharwa zvakanaka kumativi ese.

5, Kukwanisa kukuru; Mvura yakaderera; Chengetedza mari yekuomesa.

1. Sistimu yekubvisa mapfupa

2. Sisitimu yekugadzira

3. Sisitimu yekuomesa

(3) Mutsetse mutsva wekuomesa une mativi akawanda: Mutsetse wekuomesa wesimbi une mativi matanhatu unogona kuchengetedza simba rinodarika 30%

4. Kurongedza kwekubatsira kwechigadzirwa chakapedzwa

(2) Mutengesi

(3) Chinotakurwa chinotakurwa

-

Young Bamboo bepa zai tireyi kugadzira muchina auto ...

-

Marara eMapepa Ekushandisazve Kudzokorodza Zai Katoni Bhokisi reTireyi reMazai M ...

-

YB-1*3 muchina wekugadzira tireyi yezai 1000pcs/awa ye bu...

-

Otomatiki bepa pulp zai tireyi kugadzirwa mutsetse / ...

-

Muchina wekugadzira mapurasitiki ekuzadza matinji emuchina wekugadzira matinji madiki ...

-

Otomatiki marara bepa pulp zai tireyi kugadzira mach ...