Muchina we 3x4 egg tray unogona kugadzira zvidimbu 2,000 zve pulp egg trays paawa, izvo zvakakodzera kugadzirwa mumhuri diki kana muworkshop. Nekuda kwekushomeka kwayo, vatengi vazhinji vanoshandisa kuomesa kwezuva zvakananga kuti vawane mabhenefiti emari. Shandisa rack yekuomesa nemaoko kutamisa tireyi yezai paforoma, wobva washandisa trolley kusundira tireyi yezai kunzvimbo yekuomesa kuti iome. Zvichienderana nemamiriro ekunze, inowanzooma mumazuva angangoita maviri.

Mushure mekuomeswa, inounganidzwa nemaoko, yoiswa mumabhegi epurasitiki kuti isanyoroveswa, yoiswa mumapuranga uye yochengetwa mudura. Zvinhu zviri mutireyi yemapepa zvinoti mapepa emabhuku emarara, mapepanhau emarara, mabhokisi emapepa emarara, marudzi ese emapepa emarara uye zvimedu zvemapepa zvinobva mumafekitori ekudhinda nemafekitori ekupakata, marara emuswe wepepa, nezvimwewo. Vashandisi vemuenzaniso uyu wemidziyo yematura emazai vanhu 3-5: munhu mumwe chete munzvimbo yekurovera, munhu mumwe chete munzvimbo yekuumba, uye munhu mumwe kusvika vatatu munzvimbo yekuomesa.

| Muenzaniso weMuchina | 3*1 | 4*1 | 3*4 | 4*4 | 4*8 | 5*8 |

| Goho (p/h) | 1000 | 1500 | 2000 | 2500 | 4000 | 5000 |

| Pepa Remarara (kg/h) | 120 | 160 | 200 | 280 | 320 | 400 |

| Mvura (kg/h) | 300 | 380 | 450 | 560 | 650 | 750 |

| Magetsi (kw/h) | 32 | 45 | 58 | 78 | 80 | 85 |

| Nzvimbo Yemusangano | 45 | 80 | 80 | 100 | 100 | 140 |

| Nzvimbo Yokuomesa | Hapana chikonzero | 216 | 216 | 216 | 216 | 238 |

1. Sisitimu yekubvisa pulping

(1) Isa zvinhu zvakabikwa mumuchina we pulping, wedzera mvura yakakwana, wobva wakurunga kwenguva yakareba kuti pepa remarara riite pulp worichengeta mutangi rekuchengetera pulp.

(2) Isa pulp mutangi rekuchengetera pulp mutangi rekusanganisa pulp, gadzirisa huwandu hwepulp mutangi rekusanganisa pulp, uye wedzera kusanganisa mvura chena mutangi rekudzosera uye pulp yakasanganiswa mutangi rekuchengetera pulp kuburikidza ne homogenizer. Mushure mekugadziriswa kuita pulp yakakodzera, inoiswa mutangi rekugovera pulp kuti ishandiswe mu molding system.

Zvishandiso zvinoshandiswa: muchina we pulping, homogenizer, pombi ye pulping, vibrating screen, muchina we pulping

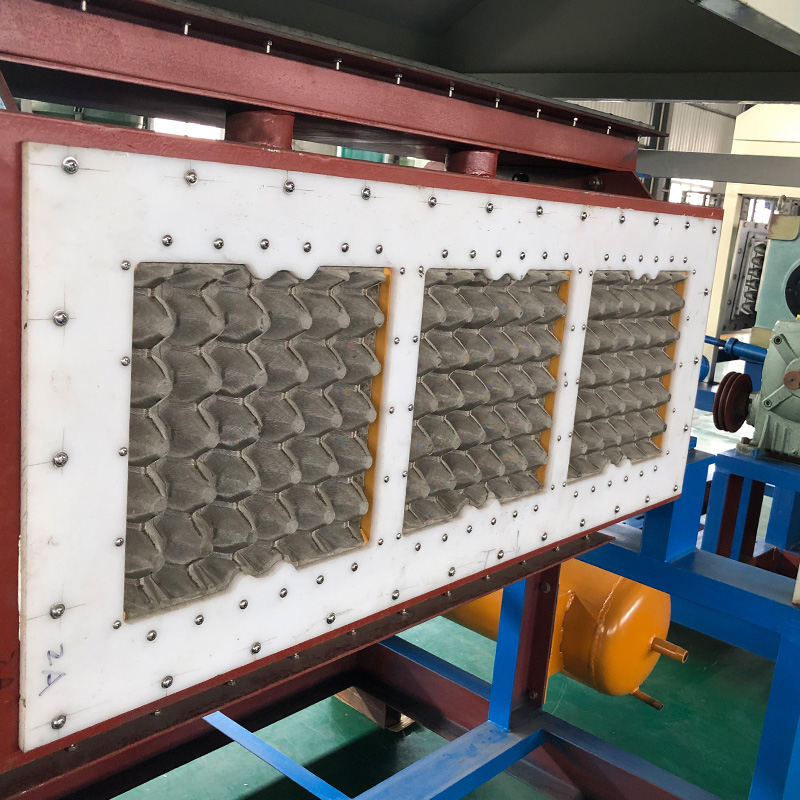

2. Sisitimu yekuumba

(1) Pulp iri mutangi rekupa pulp inoiswa mumuchina wekugadzira, uye pulp inonyungudutswa ne vacuum system. Pulp inopfuudzwa nemuforoma iri pamudziyo kuti ibve pulp iri paforoma kuti iumbwe, uye mvura chena inonyungudutswa ne vacuum pombi yodzoserwa mudziva.

(2) Mushure mekunge chakuvhuvhu chanyungudutswa, chakuvhuvhu chinopfuudzwa zvakanaka nemhepo inodzvanya, uye chigadzirwa chakaumbwa chinofuridzwa kubva pachiri kugadzira chakuvhuvhu kuenda pachiri kutamiswa, uye chakuvhuvhu chinotumirwa.

Zvishandiso zvinoshandiswa: muchina wekugadzira, chakuvhuvhu, pombi ye vacuum, tangi rekumanikidza risina simba, pombi yemvura, compressor yemhepo, muchina wekuchenesa chakuvhuvhu

3. Sisitimu yekuomesa

(1) Nzira yekuomesa yechisikigo: Teerera zvakananga kumamiriro ekunze nemhepo yechisikigo kuti zviome chigadzirwa.

(2) Kuomesa kwechinyakare: chitofu chezvidhinha, nzvimbo yekupisa inogona kusarudzwa kubva mugasi rechisikigo, dhiziri, marasha, nehuni dzakaoma, matsime ekupisa akadai segasi repetroleum rakanyungudutswa.

(3) Mutsetse wekuomesa une mativi akawanda: Mutsetse wekuomesa wesimbi une mativi matanhatu unogona kuchengetedza simba rinodarika 20% pane kuomesa kwemagetsi, uye chinhu chikuru chinopisa igesi yechisikigo, dhiziri, gasi repetroleum rakanyungudutswa, methanol nedzimwe nzvimbo dzesimba rakachena.

-

Marara eMapepa Ekushandisazve Kudzokorodza Zai Katoni Bhokisi reTireyi reMazai M ...

-

YB-1*3 muchina wekugadzira tireyi yezai 1000pcs/awa ye bu...

-

1*4 marara epepa Pulp Moulding yekuomesa tireyi yezai Ma...

-

Otomatiki bepa pulp zai tireyi kugadzirwa mutsetse / ...

-

Automatic zvizere zai tireyi kugadzira muchina zai dis ...

-

Otomatiki marara bepa pulp zai tireyi kugadzira mach ...